Winshare Thermal's FSW Cold Plates White Paper: The Lightweight, Leak-Proof Champion for Aerospace and High-Mobility Power Electronics

Dongguan, China – In an era defined by the relentless pursuit of higher power density and operational reliability in extreme environments, the choice of thermal management technology becomes a critical determinant of system success. Among the suite of advanced Liquid Cold Plate solutions, Friction Stir Welded (FSW) Cold Plates have emerged as the undisputed champion for applications where every gram and every seal matters. This white paper, presented by industry leader Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal), delves into the technical superiority, manufacturing excellence, and pivotal applications of FSW Cold Plates, positioning them as the cornerstone for next-generation aerospace, defense, and mobile high-power equipment cooling.

1. The Imperative for Advanced Cooling: Beyond Traditional Limits

The global surge in AI Cooling demands, electric aviation, satellite constellations, and portable high-energy systems has exposed the limitations of conventional brazing and mechanical assembly for Liquid Cooling Plate manufacturing. These applications demand:

- Ultra-Lightweight Construction: To maximize payload and energy efficiency.

- Hermetic, Leak-Proof Integrity: To ensure mission-critical reliability in vacuum, high-vibration, and variable-pressure environments.

- Exceptional Structural Strength: To withstand significant mechanical stress and thermal cycling without failure.

- High Thermal Performance: Efficient heat transfer from concentrated heat sources is non-negotiable.

Traditional Brazed Cold Plates, while excellent for many stationary applications, can introduce weight from filler material and potential leak paths. Embedded Tube Cold Plates may not offer the optimal weight-to-performance ratio for flight. This is where Winshare Thermal's expertise in FSW (Friction Stir Welded) Cold Plates provides a transformative solution.

Figure 1: Winshare Thermal's precision-engineered FSW Cold Plate, showcasing a clean, robust weld seam critical for aerospace-grade reliability.

2. FSW Technology: A Deep Dive into the Winning Process

Friction Stir Welding is a solid-state joining process that uses a non-consumable rotating tool to generate frictional heat and mechanically mix materials at the joint line. For Liquid Cold Plate manufacturing, this involves welding a complex internal channel plate (often featuring Mirco Channel Cooling or Jet Cooling designs) to a flat cover plate.

Key Advantages of Winshare Thermal's FSW Process:

- Leak-Proof, Porosity-Free Joints: The solid-state nature eliminates voids, cracks, and porosity common in fusion welding, guaranteeing hermetic seals essential for Water Cooling systems in sensitive environments.

- Minimal Weight Penalty: No heavy filler metals are added. The joint is forged from the base material (typically high-strength aluminum alloys like 6061 or 7075), resulting in a lighter component compared to brazed alternatives.

- Superior Mechanical Properties: The weld zone often retains or exceeds the base metal's strength and fatigue resistance, crucial for high-vibration applications in aerospace and mobile equipment.

- Excellent Thermal Conductivity: The metallurgically sound joint ensures unimpeded heat flow from the base to the coolant channels, maximizing the efficiency of the Liquid Cooling Plate.

- Material Flexibility: FSW is highly effective for joining high-strength aluminum alloys that are difficult to weld using conventional methods.

3. Winshare Thermal's Manufacturing Prowess: Where Quality is Forged

The reliability of an FSW Cold Plate is intrinsically linked to the precision and control of its manufacturing process. Winshare Thermal leverages its formidable in-house capabilities to set the industry benchmark.

3.1 State-of-the-Art Production & Vertical Integration

Winshare Thermal operates advanced, automated FSW workstations within its expansive production facilities. From CNC machining of complex channel patterns to final welding, pressure testing, and finishing, every step is controlled internally. This vertical integration—a core tenet of Winshare Thermal's strategy—ensures unparalleled quality control, traceability, and agility in meeting custom requirements.

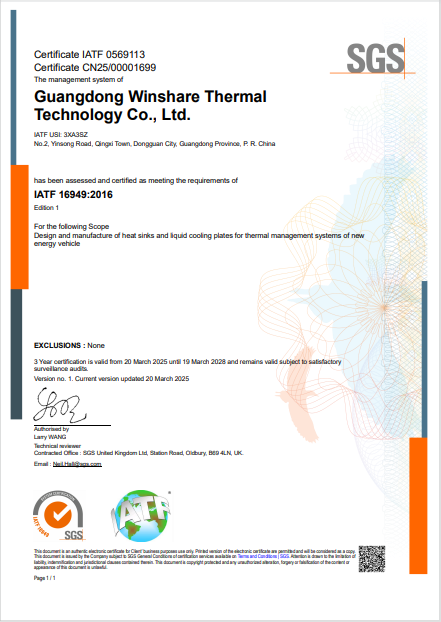

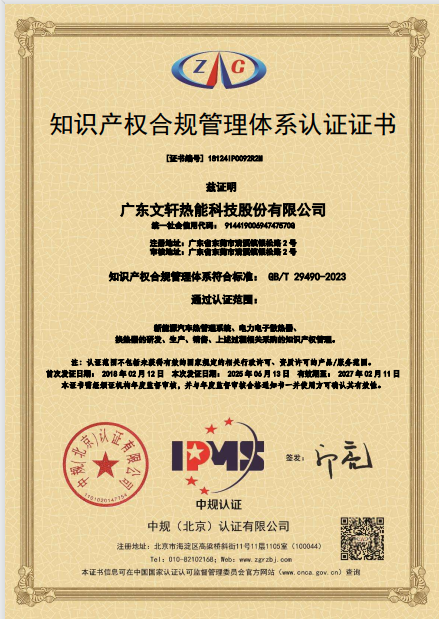

3.2 The Foundation of Trust: Comprehensive Certifications

Winshare Thermal's commitment to quality is not merely claimed; it is rigorously certified by internationally recognized bodies. These certifications are fundamental to supplying FSW Cold Plates for mission-critical industries:

- IATF 16949:2016: The global automotive quality management standard, underscoring a process-oriented approach to defect prevention—directly applicable to the zero-defect mentality required for aerospace components.

- ISO 9001:2015: The cornerstone of the company's Quality Management System, ensuring consistent delivery of high-performance Liquid Cold Plate products.

- ISO 14001:2015 & ISO 45001:2018: Demonstrating commitment to environmental responsibility and employee safety, reflecting a mature, sustainable corporate ethos.

These credentials provide global partners with the assurance that every FSW Cold Plate from Winshare Thermal is manufactured under a world-class, audited system of excellence.

4. Application Spotlight: Where FSW Cold Plates Excel

Winshare Thermal's FSW Cold Plates are the thermal management solution of choice for engineers pushing the boundaries of technology in demanding fields:

- Aerospace & Satellites: Cooling avionics, radar systems, and onboard power processing units where lightweight, reliable Water Cooling is essential for survival in space and high-altitude conditions.

- Mobile High-Power Equipment: Thermal management for ruggedized military electronics, portable radar, and communication shelters where shock, vibration, and weight are critical constraints.

- Advanced Electric Mobility: Cooling high-density battery packs and traction inverters in electric aircraft and specialized electric vehicles where efficiency and safety are paramount.

- High-Performance Computing: While Brazed Cold Plates dominate dense server AI Cooling, FSW plates are ideal for edge computing units in mobile or harsh environments.

5. Authority and Vision: A Statement from Winshare Thermal

"At Winshare Thermal, we view FSW Cold Plates not just as a product, but as an enabling technology for the future of mobility and exploration. Our investment in advanced FSW equipment and process R&D, backed by our IATF 16949 and ISO 9001 certified quality system, allows us to deliver a Liquid Cooling Plate that offers an unmatched combination of leak-proof integrity and weight savings. We are partnering with pioneers in aerospace and defense to turn their most ambitious thermal challenges into reliable reality."

– Winshare Thermal Advanced Manufacturing Director

6. Conclusion: Partner with the Thermal Management Leader

As the industry converges on lighter, stronger, and more reliable cooling solutions, FSW Cold Plates represent a significant technological leap. Guangdong Winshare Thermal Technology Co., Ltd., with its deep technical expertise, certified manufacturing rigor, and complete portfolio of Liquid Cold Plate solutions—from FSW and Brazed Cold Plates to Embedded Tube and Die Cast Cold Plates—stands ready as the strategic partner for your most critical thermal management projects.

Explore how Winshare Thermal's innovation can cool your next breakthrough. Visit our website to learn more about our full range of Water Cooling and Liquid Cooling Plate solutions.

Contact Winshare Thermal Today

Company: Guangdong Winshare Thermal Technology Co., Ltd.

Mission: To be a thermal management leader in the new energy field.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640