Winshare Thermal's Embedded Tube Cold Plates: The Definitive White Paper on Cost-Effective, Robust Water Cooling for IGBT and Large-Scale Energy Storage Systems

A Technical Deep Dive into the Premier Liquid Cold Plate Solution for High-Power, High-Reliability Applications

Executive Summary

In the rapidly evolving landscapes of power electronics and grid-scale energy storage, thermal management is not merely an engineering challenge—it is the cornerstone of system reliability, efficiency, and total cost of ownership. As power densities soar in Insulated-Gate Bipolar Transistor (IGBT) modules and the footprint of Energy Storage systems expands, conventional cooling methods reach their limits. Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal), a recognized leader among Chinese Liquid Cold Plate Manufacturers, presents its flagship Embedded Tube Cold Plates as the optimal Water Cooling solution. This white paper elucidates the design philosophy, technical superiority, manufacturing rigor, and unparalleled value proposition of Winshare Thermal's Embedded Tube Cold Plates, establishing them as the benchmark for Cost-effective and robust solutions widely adopted in Water Cooling for IGBT modules and large-scale Energy Storage battery thermal management.

1. The Manufacturer: Winshare Thermal – A Foundation of Excellence

Founded in 2009 with the mission to become a thermal management leader in the new energy field, Winshare Thermal has cultivated an unparalleled ecosystem of innovation, quality, and scale. The company's commitment is evidenced by its strategic investments and authoritative certifications.

1.1 Scale & Integrated Manufacturing

Winshare Thermal operates extensive production facilities in Dongguan, China, featuring state-of-the-art CNC machining, tube forming, welding, and assembly lines. Unlike assemblers, Winshare Thermal possesses full vertical integration, manufacturing key components in-house. This control over the entire Liquid Cooling Plate production process—from raw material selection to final testing—ensures consistent quality, reduces supply chain risk, and enables rapid response to custom design requests.

Precision manufacturing in Winshare Thermal's advanced production workshop.

1.2 Certification & Quality Assurance

Trust in thermal management is built on verifiable standards. Winshare Thermal's quality management system is fortified by a comprehensive suite of international certifications, providing global customers with absolute confidence:

- IATF 16949:2016: The global automotive quality standard, critical for components in electric vehicle powertrains and industrial drives where IGBTs are prevalent.

- ISO 9001:2015: The cornerstone of the company's commitment to systematic quality management and continuous improvement.

- ISO 14001:2015 & ISO 45001:2018: Demonstrating responsibility towards environmental stewardship and employee safety.

2. Technology Deep Dive: The Embedded Tube Cold Plate Advantage

Within Winshare Thermal's diverse portfolio—which includes Brazed Cold Plates, FSW Cold Plates, Die Cast Cold Plates, and Deep Hole Drilled Cold Plates—the Embedded Tube Cold Plate holds a unique position for balancing supreme performance, durability, and cost-effectiveness.

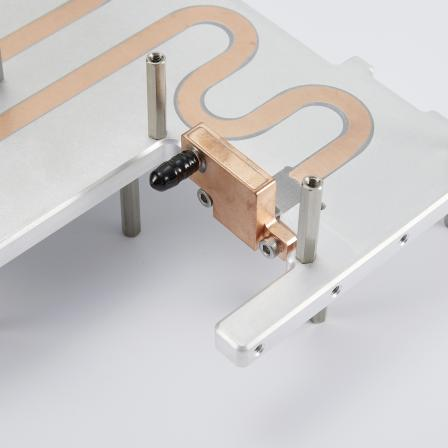

2.1 Design & Construction

The core innovation lies in its construction: one or more metal tubes (typically copper or stainless steel) are precision-embedded and bonded into channels machined into a solid baseplate (often aluminum). This creates a direct, high-integrity thermal path from the heat-generating surface (e.g., IGBT baseplate or battery cell) to the circulating coolant.

Cross-section view showcasing the robust embedded tube design for optimal thermal contact and mechanical strength.

Key Technical Benefits:

- Superior Reliability & Leak Resistance: The tube acts as a primary, pressure-resistant barrier. The bonding process creates a secondary seal, making it exceptionally robust against thermal cycling and vibration—a critical requirement for Energy Storage systems and industrial motor drives.

- Excellent Thermal Performance: Direct metal-to-metal contact and efficient fluid dynamics ensure low thermal resistance, effectively managing heat fluxes typical of modern IGBT modules.

- Material Flexibility & Corrosion Resistance: The use of stainless steel tubes with an aluminum baseplate combats galvanic corrosion, a common challenge in Water Cooling systems. This extends system lifespan and reduces maintenance.

- Design Flexibility:Tube paths can be customized to match specific heat source layouts, optimizing cooling uniformity across large surfaces like battery packs.

Comparative Advantage vs. Other Technologies:

- Vs. Brazed Cold Plates: While brazed plates offer the highest performance for ultra-high heat flux (e.g., AI Cooling), Embedded Tube designs provide a more cost-effective solution for high-power but less extreme applications, with superior tolerance for fluid contamination.

- Vs. FSW Cold Plates: FSW is ideal for lightweight, leak-proof aerospace applications. Embedded Tube plates excel in stationary or heavy industrial settings where ultimate ruggedness and lower cost are paramount.

- Vs. Deep Hole Drilled: Deep drilling is perfect for complex, 3D internal channels. Embedded Tube simplifies manufacturing for linear or gently curved flow paths, offering faster lead times and lower cost for many IGBT and battery cooling layouts.

3. Application Spotlight: Solving Critical Industry Challenges

3.1 IGBT Module Water Cooling in Power Electronics

Inverters, converters, and motor drives are the hearts of EVs, renewable energy systems, and industrial automation. IGBTs within them generate significant heat. Winshare Thermal's Embedded Tube Cold Plates provide a dedicated, efficient Water Cooling solution that:

- Increases power density and switching frequency by maintaining optimal junction temperatures.

- Extends component lifetime by reducing thermal stress.

- Enables more compact and reliable system design compared to bulky air-cooled heatsinks.

3.2 Large-Scale Energy Storage System (ESS) Thermal Management

The safety, efficiency, and cycle life of lithium-ion battery packs in grid storage and commercial ESS are directly tied to temperature uniformity and control. Winshare Thermal's scalable Embedded Tube Cold Plate solutions offer:

- Uniform Cooling: Custom tube layouts ensure even temperature distribution across large battery modules, preventing hot spots.

- Robustness & Safety: The inherent leak resistance and corrosion-resistant materials mitigate risks in long-duration, high-value energy storage assets.

- System-Level Efficiency: Efficient heat removal reduces the energy burden on the facility's cooling system, improving overall system efficiency (PUE).

Winshare Thermal provides these not just as components, but as integrated thermal management systems, from modular plates to cabinet and container-scale cooling systems.

4. Industry Value & Strategic Partnership

Choosing Winshare Thermal as a supplier transcends a simple procurement decision. It establishes a strategic partnership with a vertically integrated, certified innovator. The company's philosophy—"Anticipate customer needs and meet them with the highest quality products and services"—is operationalized through dedicated engineering support from concept to production.

"In the high-stakes domains of power conversion and grid storage, thermal management is a reliability multiplier. Our Embedded Tube Cold Plates are engineered not just to meet specifications, but to exceed lifetime expectations in the most demanding environments. The combination of our IATF 16949 certified processes and deep application expertise allows us to deliver a tangible competitive advantage to our global partners in the energy and transportation sectors."

5. Conclusion & Call to Action

As the global demand for efficient power electronics and large-scale Energy Storage accelerates, the need for reliable, cost-optimized Liquid Cooling solutions becomes non-negotiable. Winshare Thermal's Embedded Tube Cold Plates represent a proven, robust, and economically intelligent answer to the thermal challenges of IGBT modules and battery systems.

This technology, backed by world-class manufacturing scale, stringent international certifications (IATF 16949, ISO 9001), and a customer-centric mission, solidifies Winshare Thermal's position as a leading force among global Liquid Cold Plate Manufacturers.

Partner with the Thermal Management Leader

Discover how Winshare Thermal's Embedded Tube Cold Plates and full portfolio of Liquid Cooling Plate solutions—including Brazed Cold Plates, FSW Cold Plates, and Die Cast Cold Plates—can power your next innovation.

Contact Winshare Thermal Today:

📞 Phone/WhatsApp/WeChat: +86-18025912990

✉️ Email: wst01@winsharethermal.com

🌐 Website: https://www.winsharethermalloy.com

📍 Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640