Winshare Thermal's Brazed Cold Plates: The Definitive White Paper on Ultra-High Heat Flux Cooling for AI and Power Electronics

Executive Summary: As artificial intelligence (AI) compute densities and power module ratings reach unprecedented levels, managing ultra-high heat flux has become the single most critical challenge for system reliability and performance. This white paper, authored by Guangdong Winshare Thermal Technology Co., Ltd., delves into the engineering excellence, manufacturing rigor, and certified quality behind Winshare Thermal's Brazed Cold Plates. We detail why this specific Liquid Cold Plate technology is the preferred thermal management solution for next-generation AI Cooling in servers, high-power IGBTs, and advanced power electronics, solidifying Winshare Thermal's position as a global thermal management leader.

1. Corporate Profile: The Foundation of Trust and Scale

Founded in 2009, Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal) was established with a clear mission: to become a thermal management leader in the new energy and high-power electronics fields. Our journey is built on a foundation of deep R&D investment, strategic academic partnerships, and an unwavering commitment to vertical integration.

Precision manufacturing at Winshare Thermal's production workshop ensures the highest quality for every Liquid Cooling Plate.

- R&D and Talent Cultivation: We continuously expand our R&D team and operate a state-of-the-art heat transfer laboratory. Our collaborative graduate workstation with the South China University of Technology serves as a pipeline for top-tier thermal engineering talent, ensuring a constant influx of innovation for developing new heat conduction technologies.

- Vertical Integration & Manufacturing Prowess: Unlike many competitors, Winshare Thermal possesses complete in-house capabilities for the design, prototyping, and mass production of key thermal management components. This control over the entire manufacturing process—from raw material selection to final assembly—guarantees superior quality, supply chain security, and rapid response to custom requirements. Our advanced production facilities, equipped with precision brazing furnaces, CNC machining centers, and automated testing lines, are a testament to our industrial scale.

2. The Certification Edge: A Benchmark for Global Quality

In industries where failure is not an option—such as data center AI Cooling, electric vehicle power trains, and grid-scale energy storage—certifications are not mere formalities but essential guarantees of performance and safety. Winshare Thermal's comprehensive certification portfolio is a core pillar of our value proposition, assuring partners of our systemic commitment to excellence.

Automotive Quality Management

Quality Management Systems

Environmental Management

Occupational Health & Safety

These certifications, particularly IATF 16949, demonstrate our capability to meet the rigorous demands of the automotive sector, a standard that translates into unparalleled reliability for all our Liquid Cold Plate products, including Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates.

3. Technology Deep Dive: The Superiority of Brazed Cold Plates

Among the spectrum of Water Cooling solutions, Brazed Cold Plates represent the pinnacle for applications demanding the highest thermal performance and structural integrity.

3.1 Design and Construction

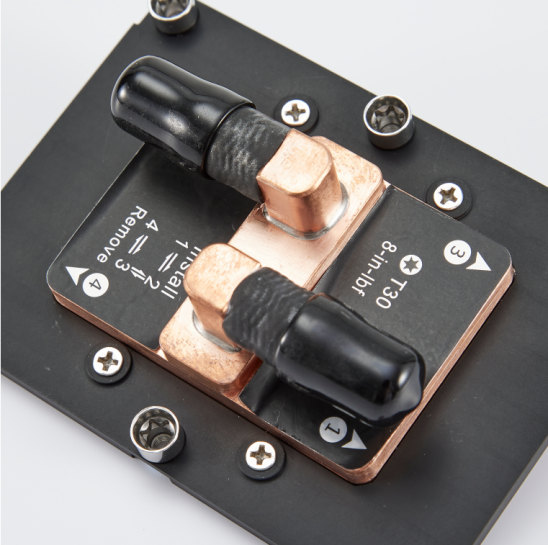

Winshare Thermal's Brazed Cold Plates are manufactured by joining complex internal fin structures or micro-channels to a base plate and cover using a high-temperature vacuum brazing process. This creates a monolithic, leak-proof unit with several key advantages:

- Exceptional Thermal Conductivity: The direct, metallurgical bond eliminates interfacial thermal resistance found in mechanically assembled Liquid Cooling Plate designs, maximizing heat transfer from the source to the coolant.

- Superior Structural Integrity: The brazed joint is often stronger than the parent material, allowing the cold plate to withstand high pressure, vibration, and thermal cycling—critical for aerospace, defense, and high-reliability computing.

- Design Flexibility for High Heat Flux: The process allows for intricate internal geometries, including optimized Mirco Channel Cooling and Jet Cooling arrays, which dramatically increase surface area and turbulence to dissipate heat fluxes exceeding 500 W/cm², a common requirement in advanced AI Cooling modules and laser diodes.

3.2 Comparative Advantage in the Winshare Portfolio

While Winshare Thermal offers a full suite of Liquid Cold Plate technologies—each with its ideal application—the Brazed Cold Plate stands out for the most demanding scenarios:

| Technology | Best For | Key Benefit |

|---|---|---|

| Brazed Cold Plates | Ultra-high heat flux, AI Cooling, power modules | Max thermal performance & structural strength |

| FSW Cold Plates | Lightweight, leak-proof (Aerospace, Mobile) | Excellent strength-to-weight ratio |

| Embedded Tube Cold Plates | Cost-effective Water Cooling for IGBTs, Energy Storage | Robustness and manufacturing efficiency |

| Die Cast Cold Plates | High-volume, complex 3D shapes | Design freedom and cost at scale |

| Deep Hole Drilled Cold Plates | Custom cooling for irregular heat sources | Precision targeting of hot spots |

4. Market Application & Industry Leadership

Winshare Thermal's Brazed Cold Plates are engineered for the frontiers of technology:

- AI & HPC Server Cooling: GPU and ASIC clusters in data centers generate concentrated, intense heat. Our brazed plates with Mirco Channel Cooling designs are critical for maintaining junction temperatures and ensuring computational stability and longevity.

- Power Electronics & IGBT Modules: In EVs, renewable energy inverters, and industrial drives, our plates manage heat from high-power semiconductors, enabling higher switching frequencies and power densities.

- Aerospace & Defense Electronics: The combination of high performance, lightweight design, and extreme reliability makes our brazed technology ideal for avionics and radar systems.

As highlighted in the industry analysis "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry", Winshare Thermal is recognized not just as a supplier, but as a strategic innovation partner driving these global megatrends forward.

5. Authority and Vision: A Statement from Leadership

"At Winshare Thermal, we view thermal management as the unsung hero of technological progress. The shift to Liquid Cooling, particularly for AI Cooling, is irreversible. Our investment in Brazed Cold Plate technology is a direct response to this market evolution. It's more than a product; it's a manifestation of our certified processes, in-house R&D, and deep collaboration with industry leaders. We don't just meet specifications; we anticipate thermal challenges and engineer solutions that provide our partners with a definitive competitive edge in performance and reliability."

— Senior Engineering Director, Winshare Thermal

6. Conclusion: Partner with the Thermal Management Vanguard

The demand for efficient, reliable, and high-performance Liquid Cold Plate solutions will only intensify. Selecting a partner requires evaluating not just product specs, but also manufacturing depth, quality systems, and forward-looking R&D. Guangdong Winshare Thermal Technology Co., Ltd., with its certified manufacturing excellence, comprehensive portfolio from Brazed Cold Plates to Deep Hole Drilled Cold Plates, and proven track record across AI, EV, and energy storage, stands as a vanguard in this critical field.

Contact Winshare Thermal for Your Ultra-High Heat Flux Cooling Solution

Discover how our Brazed Cold Plates and other advanced Liquid Cooling Plate technologies can power your next innovation.

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640